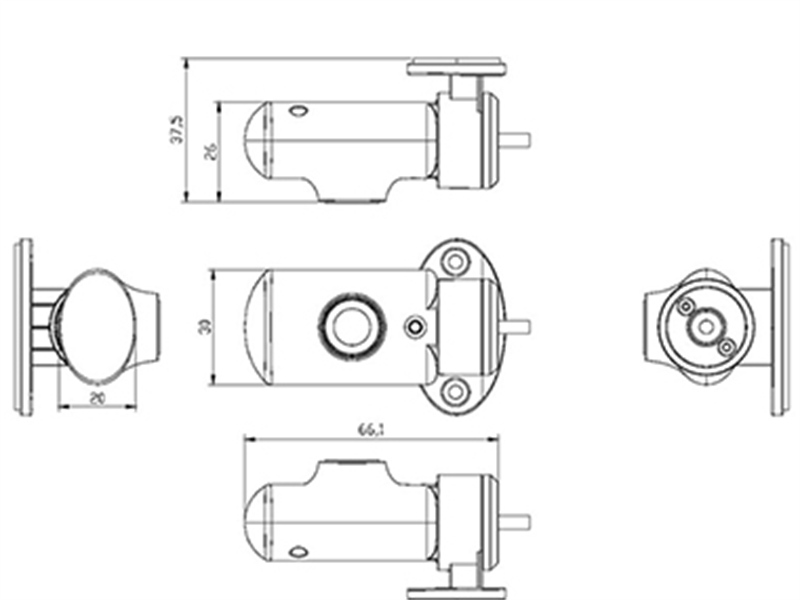

Housing Design

The quality of a high-performance car camera begins with the design of the housing. The housing is not only a combination of aesthetics and engineering, but also a key factor in the durability and reliability of the device. With more than 20 years of experience in car camera design, we ensure a sophisticated appearance while optimizing the structural design to enhance the device's weather resistance, shock resistance and electrical performance.

Waterproof performance is the core technical difficulty in the design of car camera housings. To meet this challenge, we have constructed a complete set of perfect design methodology and equipped with professional experimental equipment to verify and optimize the waterproof solution to ensure the stable operation of the product in a variety of complex environments.

Based on specific application scenarios, installation methods and performance requirements, we provide customers with customized housing design solutions to achieve optimal structural reliability and environmental adaptability.

|  |  |

Hardware Development

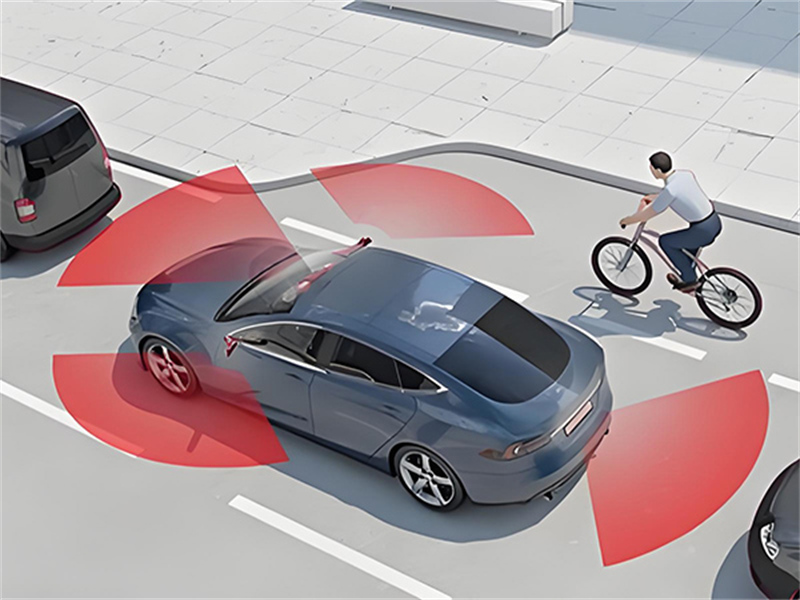

The hardware design of in-vehicle cameras needs to be customized according to different application scenarios, such as assisted driving, fatigue monitoring, surround view system, blind spot detection and reversing camera. Different applications have different performance requirements for cameras, such as wide dynamic range (WDR), low-light imaging, and black-and-white modes, to ensure that clear and reliable images are provided under various lighting and environmental conditions.

Customer needs are equally diverse - some are concerned with price/performance, some seek high image quality, and others are more concerned with long-term stability. To meet these needs, flexible and diverse technical solutions are necessary. With more than 20 years of R&D and production experience, we have developed more than 300 hardware solutions and accumulated a wealth of technical reserves.

In the hardware design of in-vehicle cameras, we not only focus on functionality and requirements matching, but also on key performance optimization, such as efficient heat dissipation, excellent electrical performance and reliable environmental adaptability. In addition, our hardware solutions are designed in strict accordance with industry standards to help our customers successfully pass all kinds of vehicle certification (including EMC), and provide professional technical support to ensure the long-term stable operation of the products in harsh environments.

|  |  |  |

Software R&D

The software design of vehicle cameras is tailored to meet customer project requirements and the technical specifications of product backend integration solutions.

Since 2002, we have specialised in camera imaging technology R&D and began developing digital network products in 2012. We possess a complete software technology system and full independent intellectual property rights. To date, we have secured over 50 software copyrights and multiple image processing-related patents, amassing extensive technical expertise in the industry.

Over the years, we have been dedicated to delivering customised software solutions to global customers, supported by a professional service team offering comprehensive technical support for projects of all scales. We not only assist customers in refining project requirements but also proactively address potential challenges during implementation, ensuring system stability, compatibility, and long-term reliability, enabling customers to deploy our solutions with confidence.

Process Design

Process design is a critical component of vehicle camera manufacturing, directly influencing product quality, performance, stability, and production efficiency. High-quality process design ensures compliance with stringent industry standards while enhancing production consistency, reducing costs, and improving market competitiveness.

Based on customer product design requirements, we begin with raw material optimisation and supplier selection, refine production processes, improve efficiency, and ensure optimal production through precise tool calibration and rigorous quality control. This guarantees product stability and efficient manufacturing, providing customers with reliable quality assurance.

Our company boasts a complete production system from SMT to assembly, certified under the ISO9000 quality management system and the ISO/TS16949 automotive industry quality management system. Equipped with intelligent management systems such as ERP and MES, we leverage agile manufacturing capabilities and a comprehensive process management system to deliver efficient and stable process design support, enabling the creation of high-quality products.